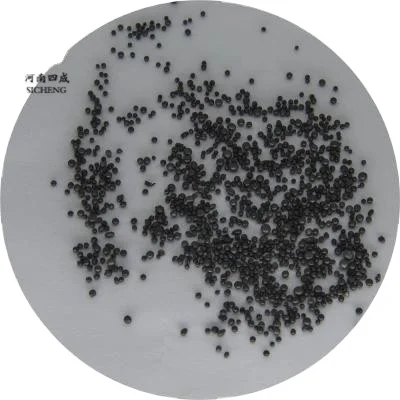

Ceramic sand is produced by adding the electric arc furnace containing Al2O3 45%-90% raw bauxite ore, the high temperature produced by the arc of the arc discharge, the raw material bauxite melted liquid, the liquid flows out of the furnace, impose its 70-85m/s to air pressure, the liquid material with the strong wind crushing, cooled to obtain spherical or nearly spherical shape, smooth sand performance. ceramic casting sand ceramic casting sand ceramic casting sand ceramic casting sand

Grain type | ball, spherical |

Angularity | 1.1 max, similar to ball |

Bulk density | 1.95-2.05 g/cm3 |

Refractoriness | 1790℃ |

Thermal expansion | 0.13% (10 min at 1000 C ) |

Size | Available in all models, it can also be customized |

Composition | Content |

Al2O3 | 70-75% |

SiO2 | 8-20% |

Fe2O3 | ≤ 3% |

TiO2 | ≤ 3.5 % |

CaO | ≤ 0.45 % |

MgO | ≤ 0.35 % |

K2O | ≤ 0.33% |

Na2O | ≤ 0.08 % |

Customer Vist

Packing List

1. 25kg woven bag, 40 woven bags/jumbo bag.

2. 25kg woven bag, 40 woven bags/pallet

3. 25kg paper bag, 40 paper bags/pallet

4. 1MT Jumbo bag.

Packing can be customized according to customer’s requirements

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.